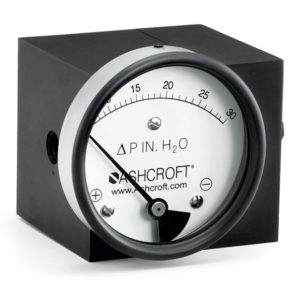

1134 Differential Pressure Gauge

1134 Differential Pressure Gauge

The Ashcroft® 1134 differential pressure gauge is an economical means for measuring very low pressure between two independent pressure sources.

Features & Properties

Use & Application

Downloads

Features & Properties

Use & Application

The 1134 differential gauge is ideal where safe and reliable pressure measurement is essential:

- Filtration Monitoring

- Flow Measurement

- Leak Detection

- Clean Room Positive Pressure (low dp)

Downloads

Data Sheets

Installation + Maintenance

Declaration of Conformity

Selection Guides

The Ashcroft® 1134 differential pressure gauge is an economical means for measuring differential pressure. The 1134 is designed for mounting in clean room, isolation room and glove box applications and offers ranges as low as 2.5 mbar

Key Features

Flow measurement dial (optional)

Superior magnets for smoother pointer motion

Stainless steel case for limited space

Electrical contacts (optional)

Custom dials available

Standard with in-line and back process ports

Cost effective

Markets & Applications

- Specifications

- Downloads

Case Style

Safety by design measures (S3)

Dial Size

4 1/2"

Switch Style

Reed contacts SPST or SPDT

Process Connection Style

Threaded

Ranges

2.5 ... 125 mbar / 0.6 ... 60 in. H2O

Wetted Parts Material

Glass filled nylon

O-Rings/Diaphragm Buna-N or EPDM

Ingress Protection

IP65

Accuracy

3% ascending

Case or Body Material

Stainless steel 304 (1.4301)

Pressure Type

Differential pressure

Process Connection Location

In-line

Centre back

Mounting

2" pipe mounting

Flush

Stem

Surface

Static Pressure

2.4 bar / 35 psid

Data Sheets

Installation + Maintenance

Declaration of Conformity

Selection Guides

- Category: Differential Gauges

We’re glad to be there for you personally.

Siamo personalmente a vostra disposizione!

Nous sommes personnellement là pour vous.

Şahsen yanınızda olmaktan mutluluk duyuyoruz.

We zijn blij dat we er persoonlijk voor u kunnen zijn.

Wir sind persönlich für Sie da!

Siamo personalmente a vostra disposizione!

Nous sommes personnellement là pour vous!

Select your Region!