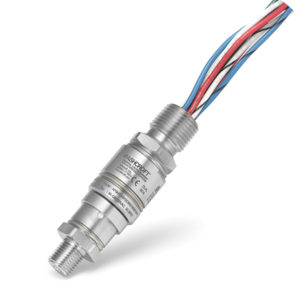

VP-Series Pneumatic Pressure Switch

VP-Series Pneumatic Pressure Switch

The Ashcroft® VP pneumatic pressure switch was designed for use with harsh applications where uncompromising protection is required.

Features & Properties

Use & Application

Downloads

Features & Properties

Use & Application

The VP pneumatic pressure switch is ideal where accurate and reliable pressure measurement are essential:

Downloads

Data Sheets

Installation + Maintenance

Drawings + Models

The Ashcroft® VP pneumatic pressure switch is designed for use on tough applications where no electric power is available and uncompromising protection is required. The features of this switch along with its proven technology provide a stable, long-lasting product. Ideal for pressure control, safety shutdown or alarm operations.

Key Features

Selection of wetted materials

Precise repeatability of setpoint

Adjustable setpoints from 15% ... 100% of range

Wide variety of pressure connection thread options

Markets & Applications

Water and Wastewater

Chemical and Petrochemical

- Specifications

- Downloads

Switch Style

5/2 way pneumatic valve

Process Connection Style

Threaded

Accuracy

1% of span

Ranges

Vacuum

1 ... 210 bar / 15 ... 3000 psi

Compound

25 ... 375 mbar / 10 ... 150 in. H2O

Wetted Parts Material

Buna-N®

Teflon®

Viton®

Stainless steel 316L (1.4404)

Monel

Pressure Type

Gauge pressure

Ingress Protection

IP65

Case or Body Material

Epoxy coated aluminium

Process Connection Location

Lower

Setpoint

Single setpoint - Field adjustable

Deadband Fixed

Mounting

Surface

2" pipe mounting

Stem

Data Sheets

Installation + Maintenance

Drawings + Models

- Category: Pressure Switches

We’re glad to be there for you personally.

Siamo personalmente a vostra disposizione!

Nous sommes personnellement là pour vous.

Şahsen yanınızda olmaktan mutluluk duyuyoruz.

We zijn blij dat we er persoonlijk voor u kunnen zijn.

Wir sind persönlich für Sie da!

Siamo personalmente a vostra disposizione!

Nous sommes personnellement là pour vous!

Select your Region!