ASHCROFT DIAPHRAGM SEAL EXPERTISE

ASHCROFT DIAPHRAGM SEAL EXPERTISE

- Low and high temperature applications

- Food industry

- Pharmaceutical industry

- Processes with highly reactive media

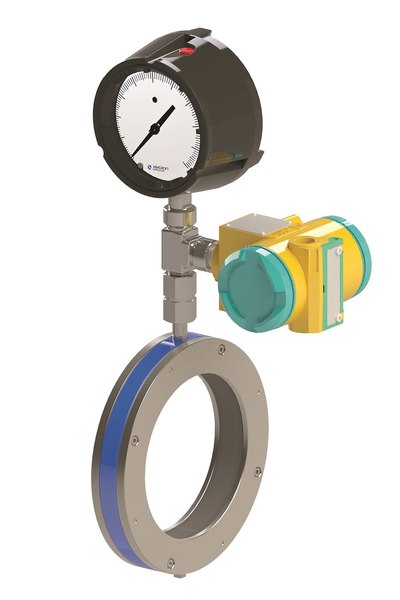

Not only do we manufacture pressure, temperature and level instruments at our European manufacturing facility, but we also maintain our centre of excellence for diaphragm seals and diaphragm seal systems there.Here we combine our research and development expertise with state-of-the-art manufacturing and calibration capabilities. Our diaphragm seals and diaphragm seal systems are the result of our many years of development work and application experience.

MANUFACTURING & METHODOLOGY

In dialogue with our customers, we develop application and user-specific solutions. We also rely on software-based simulations to calculate diaphragm performance based on finite element methodology.A smart production line with modern welding technology and in-house developed filling stations enable technically and economically interesting product solutions while ensuring fast and reliable delivery times.

MATERIALS & SPECIAL MATERIALS

The standard material of our flanges and diaphragms is 316L dual grade stainless steel.The welding technology used also offers a maximum range of special materials for the diaphragm, which is applied to the standard stainless steel flange or a flange made of special material.Thus we offer diaphragm seal systems with the following materials:Stainless steel DuplexMonelHastelloyInconelTantalumGold platedTitaniumPTFE coatedECTFE coated

TYPES OF MOUNTING

Various types of mounting are possible, such as:Direct mountingAttachment with capillaryAsymmetrical systems (for differential pressure measurement)

FILLING FLUIDS

A complete portfolio of different filling fluids makes our diaphragm seal systems suitable for applications inLow and high temperature applicationsFood industryPharmaceutical industryProcesses with highly reactive mediaFurthermore, the filling fluids used optimise the dynamic response of the diaphragm seal system.Our design is always tamper-proof and process-safe due to the use of fully welded components.

CALIBRATION

We calibrate the entire system, taking into account the overall geometric situation in the subsequent application. We also take into account the specified process and ambient temperatures and calculate the system response time and the possible temperature influence.

PRODUCT SOLUTIONS

We realise our diaphragm seal systems for our own as well as third-party products and create solutions for:Pressure gaugesPressure switchesTransmittersPressure transmittersDigital pressure gauges

SERVICE / MAINTENANCE / REPAIR

Our services do not only concentrate on new systems. We are also able to maintain and repair an existing system in a professional and reliable manner. We can also reliably calibrate an existing system thanks to the expertise of our DAkkS accredited test laboratory.

- Specifications

- Downloads

- Category: Smart transmitter assemblies