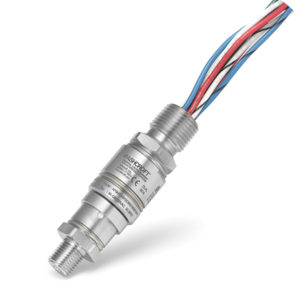

A-Series Watertight Pressure Switch

A-Series Watertight Pressure Switch

Data Sheets

Installation + Maintenance

Declaration of Conformity

- 📄 SIL certificate A-series pressure switch 🇬🇧

- 📄 SIL 3 Manual A-series switch 🇬🇧

- 📄 EAC Declaration of Conformity 🇬🇧

- 📄 EUdeclaration of conformity CE A-Switch 🇬🇧

- 📄 EU DoC AP_N4 Switch 09-2018 🇬🇧

Industry Brochures

- 📄 Instrumentation for Water Treatment and Waste Water Industries 🇬🇧

- 📄 Instrumentation for Air Conditioning, Heating and Refrigeration Industries 🇬🇧

- 📄 Catalogue Hygienic Applications 🇬🇧

Product + Technical Information

- 📄 Product Information Page Sanitary Switches SW-PI-55 🇬🇧

- 📄 Product Information Page Product Information page Switch for Level Control SW-PI-50 🇬🇧

- 📄 Product Information Page Switch Oxygen Cleaning SW-PI-06B 🇬🇧

- 📄 Product Information Page Instrinsic Safety SW-PI-66 🇬🇧

- 📄 Product Information Page Switch Diaphragm Seal Combo SW-PI-30E 🇬🇧

- 📄 Product Information Page Switch A Series Date Code Identification SW-PI-80 🇬🇧

- 📄 Product Information Page Eight Steps to Selecting a Switch SW-PI-70A 🇬🇧

- 📄 Product Information Page Conventing Old A Series to New A Series Part Numbers SW-PI-77A 🇬🇧

Drawings + Models

- 📄 Drawing Watertight Pressure Switch APS N4 XC 🇬🇧

- 📄 Drawing Watertight Pressure Switch APS N4 00MH 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000T-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012L-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012L-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-01 🇬🇧

- 📄 Ashcroft A Series Watertight Pressure Switch Drawing Index 🇬🇧

Key Features

316L stainless steel enclosure provides uncompromising protection

Wide operating temperature -40°C to 100°C

Expanded selection of pressure and electrical connections

SIL 3 Capable

UL, CSA, CE, CRN and 3A approved

Markets & Applications

Food and Beverage

Oil and Gas

Machine Automation

Hydrogen and Technical Gases

Pharmaceuticals

Pumps and Compressors

Pulp and Paper

Chemical and Petrochemical

Energy

- Specifications

- Downloads

Ranges

Compound

1 ... 1000 bar / 15000 psi

Electrical Termination

Hirschmann EN 175301-803 Form A

1/2 NPT male conduit

M20x1.5 male conduit

Hirschmann EN 175301-803 Form C

AMP® Superseal® 3-Pin

Metri-Pack® 3-Pin

Deutsch® DT04-3P

Spade Terminals

M12 Hirschmann® 993-172-100

Wire leads, PVC insulated

Wetted Parts Material

Stainless steel 316L (1.4404)

Buna or Viton O-rings

Setpoint

Single setpoint - Factory set

Single setpoint - Field adjustable

Deadband Fixed

Ingress Protection

IP67 / NEMA 6

Case or Body Material

Stainless steel 316L (1.4404)

Process Connection Style

¾˝ Tri-Clamp®

1½˝ or 2˝ Tri-Clamp®

VCR or VCO fitting

Threaded

Tube stub male

Accuracy

5% of span for ranges -1/1 to 7 bar

2% of span for ranges from 14 bar

Pressure Type

Gauge pressure

Switch Style

Microswitch DPDT

Microswitch SPDT

Data Sheets

Installation + Maintenance

Declaration of Conformity

- 📄 SIL certificate A-series pressure switch 🇬🇧

- 📄 SIL 3 Manual A-series switch 🇬🇧

- 📄 EAC Declaration of Conformity 🇬🇧

- 📄 EUdeclaration of conformity CE A-Switch 🇬🇧

- 📄 EU DoC AP_N4 Switch 09-2018 🇬🇧

Industry Brochures

- 📄 Instrumentation for Water Treatment and Waste Water Industries 🇬🇧

- 📄 Instrumentation for Air Conditioning, Heating and Refrigeration Industries 🇬🇧

- 📄 Catalogue Hygienic Applications 🇬🇧

Product + Technical Information

- 📄 Product Information Page Sanitary Switches SW-PI-55 🇬🇧

- 📄 Product Information Page Product Information page Switch for Level Control SW-PI-50 🇬🇧

- 📄 Product Information Page Switch Oxygen Cleaning SW-PI-06B 🇬🇧

- 📄 Product Information Page Instrinsic Safety SW-PI-66 🇬🇧

- 📄 Product Information Page Switch Diaphragm Seal Combo SW-PI-30E 🇬🇧

- 📄 Product Information Page Switch A Series Date Code Identification SW-PI-80 🇬🇧

- 📄 Product Information Page Eight Steps to Selecting a Switch SW-PI-70A 🇬🇧

- 📄 Product Information Page Conventing Old A Series to New A Series Part Numbers SW-PI-77A 🇬🇧

Drawings + Models

- 📄 Drawing Watertight Pressure Switch APS N4 XC 🇬🇧

- 📄 Drawing Watertight Pressure Switch APS N4 00MH 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012L-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P012C-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000T-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1P000H-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012L-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H012C-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-01 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000T-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-75 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-25 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-20 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-15 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-07 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-06 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-05 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-03 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-02 🇬🇧

- 📄 Drawing Pressure Switch APSN4 1H000H-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000T-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012L-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012L-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P012C-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1P000H-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012L-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H012C-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-05 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000T-01 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-75 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-25 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-20 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-15 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-07 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-06 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-03 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-02 🇬🇧

- 📄 Drawing Pressure Switch APAN4 1H000H-01 🇬🇧

- 📄 Ashcroft A Series Watertight Pressure Switch Drawing Index 🇬🇧

- Category: Pressure Switches