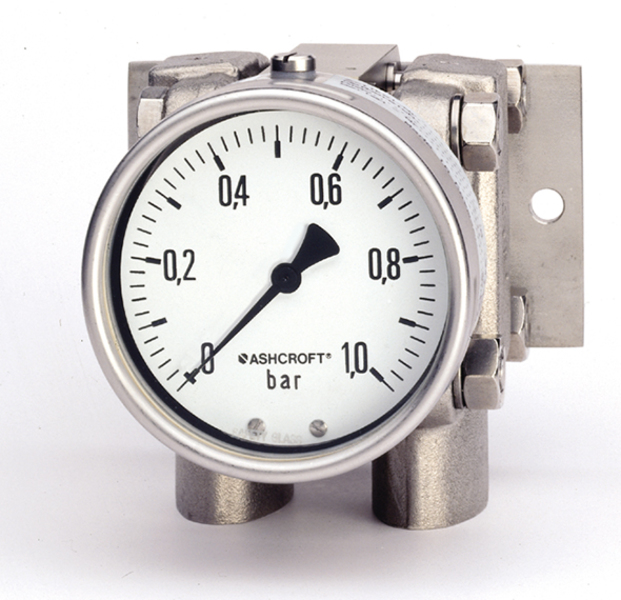

F5503 Differential Pressure Gauge

F5503 Differential Pressure Gauge

Data Sheets

Installation + Maintenance

Declaration of Conformity

- 📄 ATEX EU DoC F5503 08-2022 🇩🇪🇬🇧

- 📄 ATEX EU DoC F5503 with inductive proximity switch/mit Induktivkontakt 08-2022 🇩🇪🇬🇧

- 📄 EU DoC Pressure Gauge / Manometer 12-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC F5503 08-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC F5503 with inductive proximity switch/mit Induktivkontakt 08-2022 🇩🇪🇬🇧

- 📄 UKCA DoC Pressure Gauge / Manometer 11-2022 🇩🇪🇬🇧

Industry Brochures

Selection Guides

Product + Technical Information

- 📄 Product Information Page AShcroft Products Size Weights – ASH-PI-64 🇬🇧

- 📄 Product Information Page Product for Sour Oilfield NACE MRO0175 and Sour Petroleum Refining Operations NACE MRO0103 ASH-PI-60D 🇬🇧

- 📄 Product Information Page Artwork Submittal Requirements for Custom Dials ASH-PI-63 🇬🇧

Drawings + Models

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 0,6 – 40 Bar XTM 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 0,6 – 40 Bar XFF1 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 0,6 – 40 Bar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 40 – 400 mbar XTM 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 40 – 400 mbar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 0,6 – 40 bar XTM 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 0,6 – 40 bar XFW Contact 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 0,6 – 40 mbar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 – 400 mbar XTM T 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 – 400 mbar XFF 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 – 400 mbar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 – 400 mbar XTM 🇬🇧

Safety Data Sheets

Key Features

Electrical contacts (optional)

Flow measurement dial (optional)

NACE compliant (optional)

Ability to attach to diaphragm seals

Rugged stainless steel construction

Selection of wetted materials

Extremely High static pressure limits

External zero adjustment

Markets & Applications

Energy

Food and Beverage

Water and Wastewater

Oil and Gas

Refinery

Level and Flow Measurement

Machine Automation

Hydrogen and Technical Gases

Pharmaceuticals

Pumps and Compressors

Chemical and Petrochemical

- Specifications

- Downloads

Ingress Protection

IP66 / NEMA 4

Static Pressure

PN100

PN160

PN250

PN400

Case or Body Material

Stainless steel 304 (1.4301)

Stainless steel 316L (1.4404)

Process Connection Style

Threaded

Oval flange DIN 61518

Accuracy

0.5% of span (optional)

1.6% of span (class 1.6)

1% of span (optional)

Process Connection Location

Lower

Case Style

Safety by design measures (S3)

Mounting

2" pipe mounting

Stem

Surface

Pressure Type

Differential pressure

Dial Size

100 mm

160 mm

Switch Style

Magnetic spring contacts

Inductive NAMUR contacts

Dampening

Liquid fill

Ranges

25 ... 1000 mbar / 10 in.H2O ... 15 psi

1 ... 40 bar / 600 psi

Wetted Parts Material

Stainless steel 316L (1.4404)

Monel

Hastelloy C

Data Sheets

Installation + Maintenance

Declaration of Conformity

- 📄 ATEX EU DoC F5503 08-2022 🇩🇪🇬🇧

- 📄 ATEX EU DoC F5503 with inductive proximity switch/mit Induktivkontakt 08-2022 🇩🇪🇬🇧

- 📄 EU DoC Pressure Gauge / Manometer 12-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC F5503 08-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC F5503 with inductive proximity switch/mit Induktivkontakt 08-2022 🇩🇪🇬🇧

- 📄 UKCA DoC Pressure Gauge / Manometer 11-2022 🇩🇪🇬🇧

Industry Brochures

Selection Guides

Product + Technical Information

- 📄 Product Information Page AShcroft Products Size Weights - ASH-PI-64 🇬🇧

- 📄 Product Information Page Product for Sour Oilfield NACE MRO0175 and Sour Petroleum Refining Operations NACE MRO0103 ASH-PI-60D 🇬🇧

- 📄 Product Information Page Artwork Submittal Requirements for Custom Dials ASH-PI-63 🇬🇧

Drawings + Models

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 0,6 - 40 Bar XTM 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 0,6 - 40 Bar XFF1 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 0,6 - 40 Bar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 40 - 400 mbar XTM 🇬🇧

- 📄 Drawing Differential Pressure Gauge 160 F5503 L 40 - 400 mbar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 0,6 - 40 bar XTM 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 0,6 - 40 bar XFW Contact 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 0,6 - 40 mbar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 - 400 mbar XTM T 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 - 400 mbar XFF 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 - 400 mbar XFW 🇬🇧

- 📄 Drawing Differential Pressure Gauge 100 F5503 L 40 - 400 mbar XTM 🇬🇧

Safety Data Sheets

- Category: Differential Gauges, Process Gauges