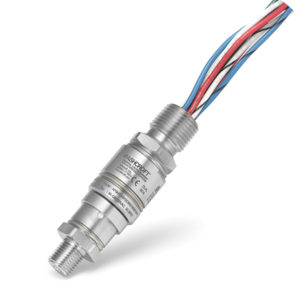

B-Series NEMA 7/9 Pressure Switch

B-Series NEMA 7/9 Pressure Switch

Data Sheets

Installation + Maintenance

Declaration of Conformity

- 📄 EAC Ex Declaration of Conformity 🇬🇧

- 📄 B, D and T Switch Safety Manual 🇬🇧

- 📄 SIL certificate B, D & T switch 🇬🇧

- 📄 EAC Declaration of Conformity 🇬🇧

- 📄 ATEX EU DoC B7 D7 T7 Exd 1391X 08-2022 🇩🇪🇬🇧

- 📄 ATEX EU DoC B7 D7 T7 Exia 2081X 08-2022 🇩🇪🇬🇧

- 📄 EU DoC Switch Series B-D-T-L-G-P-F 09-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC B7 D7 T7 Exd 1391X 08-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC B7 D7 T7 Exia 2081X 08-2022 🇩🇪🇬🇧

Industry Brochures

- 📄 Catalogue Oil & Gas 🇬🇧

- 📄 Instrumentation for Air Conditioning, Heating and Refrigeration Industries 🇬🇧

Product + Technical Information

- 📄 Product Information Page Sanitary Switches SW-PI-55 🇬🇧

- 📄 Product Information Page Product Information page Switch for Level Control SW-PI-50 🇬🇧

- 📄 Product Information Page Sealed Conduit Connection SW-PI-54 🇬🇧

- 📄 Product Information Page Switch Oxygen Cleaning SW-PI-06B 🇬🇧

- 📄 Product Information Page Switch Medium Pressure Gas and Oil Limit SW-PI-28 🇬🇧

- 📄 Product Information Page Switch Info and Guidelines SW-PI-62 🇬🇧

- 📄 Product Information Page Switch Dial Seal Rating SW-PI-76 🇬🇧

- 📄 Product Information Page Switch Dual Diaphragm XG7 SW-PI-56 🇬🇧

- 📄 Product Information Page Switch Diaphragm Seal Combo SW-PI-30E 🇬🇧

- 📄 Product Information Page Switch Belleville Actuator XG3 SW-PI-58 🇬🇧

- 📄 Product Information Page Eight Steps to Selecting a Switch SW-PI-70A 🇬🇧

- 📄 Product Information Page Product for Sour Oilfield NACE MRO0175 and Sour Petroleum Refining Operations NACE MRO0103 ASH-PI-60D 🇬🇧

Drawings + Models

- 📄 Drawing Pressure Switch B700 INH2O CN 06 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 07 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 06 XJM XTM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 06 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 06 XJL XTM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 15 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 25 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 15 CEN3 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 15 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 13 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 07 XCEN3 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 07 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 B,T,V 1000-3000 PSI CN 07 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 06 XJM XCH 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 06 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 06 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 02 XJL 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI IP 07 XJL 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI IP 06 XJL 🇬🇧

Key Features

SIL 3 Capable

Adjustable setpoints from 15% ... 100% of range

Explosion-proof housing provides uncompromising protection

Wide selection of switch elements

CE, CRN and 3A approved

Internal setpoint locking screw

UL, CSA, ATEX and IECEx hazardous approvals

316L Stainless Steel housing available

Markets & Applications

Chemical and Petrochemical

Energy

Boilers

Gas Measurement; Burners

Food and Beverage

Oil and Gas

Pulp and Paper

Machine Automation

Water and Wastewater

Hydrogen and Technical Gases

Pharmaceuticals

Pumps and Compressors

HVAC-R

- Specifications

- Downloads

Ranges

1 ... 210 bar / 15 ... 3000 psi

25 ... 375 mbar / 10 ... 150 in. H2O

Vacuum

Compound

Wetted Parts Material

Viton®

Stainless steel 316L (1.4404)

Monel

Buna-N®

Teflon®

Pressure Type

Gauge pressure

Ingress Protection

IP66 / NEMA 7/9

Setpoint

Single setpoint - Field adjustable

Deadband Fixed

Deadband limited adjustable

Case or Body Material

Stainless steel 316L (1.4404)

Epoxy coated aluminium

Electrical Termination

3/4 NPT female

1/2 NPT female

M20x1.5 female

Cable gland Ex d

Process Connection Location

Lower

Mounting

Stem

Surface

2" pipe mounting

Switch Style

Microswitch SPDT

Microswitch DPDT

Process Connection Style

Threaded

Accuracy

1% of span

Data Sheets

Installation + Maintenance

Declaration of Conformity

- 📄 EAC Ex Declaration of Conformity 🇬🇧

- 📄 B, D and T Switch Safety Manual 🇬🇧

- 📄 SIL certificate B, D & T switch 🇬🇧

- 📄 EAC Declaration of Conformity 🇬🇧

- 📄 ATEX EU DoC B7 D7 T7 Exd 1391X 08-2022 🇩🇪🇬🇧

- 📄 ATEX EU DoC B7 D7 T7 Exia 2081X 08-2022 🇩🇪🇬🇧

- 📄 EU DoC Switch Series B-D-T-L-G-P-F 09-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC B7 D7 T7 Exd 1391X 08-2022 🇩🇪🇬🇧

- 📄 UKCA UKEX DoC B7 D7 T7 Exia 2081X 08-2022 🇩🇪🇬🇧

Industry Brochures

- 📄 Catalogue Oil & Gas 🇬🇧

- 📄 Instrumentation for Air Conditioning, Heating and Refrigeration Industries 🇬🇧

Product + Technical Information

- 📄 Product Information Page Sanitary Switches SW-PI-55 🇬🇧

- 📄 Product Information Page Product Information page Switch for Level Control SW-PI-50 🇬🇧

- 📄 Product Information Page Sealed Conduit Connection SW-PI-54 🇬🇧

- 📄 Product Information Page Switch Oxygen Cleaning SW-PI-06B 🇬🇧

- 📄 Product Information Page Switch Medium Pressure Gas and Oil Limit SW-PI-28 🇬🇧

- 📄 Product Information Page Switch Info and Guidelines SW-PI-62 🇬🇧

- 📄 Product Information Page Switch Dial Seal Rating SW-PI-76 🇬🇧

- 📄 Product Information Page Switch Dual Diaphragm XG7 SW-PI-56 🇬🇧

- 📄 Product Information Page Switch Diaphragm Seal Combo SW-PI-30E 🇬🇧

- 📄 Product Information Page Switch Belleville Actuator XG3 SW-PI-58 🇬🇧

- 📄 Product Information Page Eight Steps to Selecting a Switch SW-PI-70A 🇬🇧

- 📄 Product Information Page Product for Sour Oilfield NACE MRO0175 and Sour Petroleum Refining Operations NACE MRO0103 ASH-PI-60D 🇬🇧

Drawings + Models

- 📄 Drawing Pressure Switch B700 INH2O CN 06 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 07 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 06 XJM XTM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 06 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CEN6 06 XJL XTM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 15 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 25 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 15 CEN3 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 15 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 13 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 07 XCEN3 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 07 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 B,T,V 1000-3000 PSI CN 07 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 06 XJM XCH 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 06 XJM 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 06 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI CN 02 XJL 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI IP 07 XJL 🇬🇧

- 📄 Drawing Pressure Switch B700 PSI IP 06 XJL 🇬🇧

- Category: Pressure Switches